For industries

Board packaging

Solutions for smart, automatic, and cost-efficient board packaging

Board packaging automation takes the product flow to the next level

How smart is your board packaging operation line? Are your packages easy to stack and move, can you shelter them from moisture, and does the package give a good look for your high-quality products?

It’s time to rethink the traditional board packaging. With the help of automation, your packaging line can meet the new generation’s requirements for efficiency and quality. This means that you can forget the manual hard work while your packages are waterproof, first-class quality, and more environmentally friendly.

It goes without saying that automation will also improve your board packaging operation without increasing costs.

The new generation’s solution from Cross Wrap

Compared to traditional strapping, hooding, or manual packaging, an automated board packaging line will boost your competitive edge. With automation, you can pack boards of different sizes while improving the quality and reducing labor costs.

The traditional way of packing is usually manual or semi-automatic. You might pack stacks of boards with a pallet placed beneath the boards and covers strapped at the corners in an attempt to minimize damage.

This old way also requires at least two employees per shift, and four to five different packaging materials, which can lead to high consumable costs. On top of that, the packaging materials require a lot of storage space.

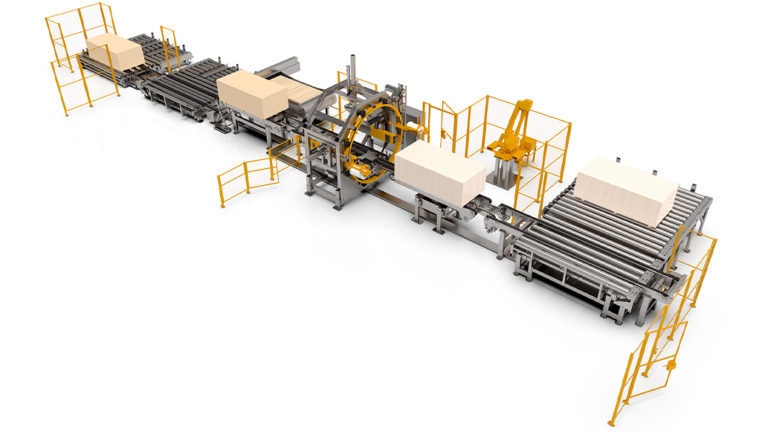

We offer you the new generation’s solution for board packaging. You can say goodbye to the cost and hassles of a strapping unit! The CW packaging line operates fully automatically.

What makes the CW board packaging solution so unique?

– Fully automatic, and there is no need for manual operation at any stage.

– Reduce your labor costs and improve the safety of your facility.

– All-sides covered protection for packages safeguards boards against multiple handlings, extreme weather, and transport conditions.

– Packages variable sizes of board stacks on the very same line.

Wrap tightly, handle and transport easily

Have your packages ever been damaged during transport or storing? Our unique wrapping technique ensures that you can handle and transport your packages without any loss in value.

- Since the wrapping method is very durable, you can transport your wrapped board packages even laying on their sides if you wish.

- Wrapped boards do not come loose during transport.

- Compared to the old strapping method, the boards placed at the very top and bottom on board stacks also remain unharmed.

The wrapping is durable but gentle, so the sides of boards remain in a better condition. You can also take out a board from the stack without the entire package falling apart!

When thinking about the handling and transport of traditional, strap-tied products, boards are free to slip, and straps are unable to handle the shifting weight and hold boards together. And when strapped boards are stored on top of each other, the straps on the bottom can loosen. This causes even more board slipping and shifting, and potentially more board damage.

By using Cross Wrap Board Packaging you get an evenly tight and weatherproof package that is exceptionally strong and durable.

How come there is no moisture in the package?

For a long time, unwanted moisture has been a problem that decreases the quality of board products.

Moisture enters non-wrapped packages easily if they are stored or transported outdoors. When board stacks aren’t enclosed on all six sides, especially the top and bottom, it leaves boards much more vulnerable to quality issues and serious damage caused by unwanted moisture.

There has also been a belief that packages should be able to “breathe”, but in reality, this doesn’t have an effect on the quality.

The best solution to prevent moisture is to cover the package on all sides. Our automated packaging line wraps packages efficiently on all six sides.

The moisture in the air or on the ground won’t be able to penetrate the waterproof film, keeping the material’s quality intact. Naturally, the package also protects against dirt and pests.

More environmentally friendly packaging

Automated labeling places labels under the film, which is an important detail. The label is sheltered from moisture and dirt, which often wears out paper labels. Your package content is easy to recognize since the label will not accidentally fall out from underneath the film.

We shouldn’t forget the environmental impact of labels. Ours are always made of recyclable paper. Thus, we reduce the amount of non-recyclable waste because traditional sticky labels often end up in landfills.

First-class packaging for your high-quality products

The package’s mission is not just to protect, but also represent your products. Does your package give a good first impression? Is it clean and neat, or weary and moist?

Our wrapping ensures that your high-quality products are packed with first-class methods. A clean and firm package enhances your product presentation instantly.

If your customer gets to choose between two packages, they will choose the one that is presentable. With our packaging methods, the contents will not become dirty, the film will not detach, and the corners will not come loose. And the end customers appreciate a package that is easy to store also on their premises.

CUSTOMER STORY – URUPLY

Uruguay-based plywood manufacturer Uruply S.A. has been using the automated CW Board Packaging Line since 2007. The line has changed the game into a high-capacity line that now operates more cost-effectively with a better package quality.

“The Cross Wrapped packages are easy to handle and to store. The wrapping offers a durable package that brings us many benefits over the more traditional packaging methods.“

“These benefits are a stronger and waterproof package, easy-to-recycle packaging materials, good-looking package, and the fact that there are fewer transport damages to the products.”

Mr. Claudio Brasesco, the Maintenance Manager for Uruply S.A. Tacuarembó mill.

A smart way to pack it – fully automated CW Packaging Line

- Suitable for all kinds of boards, including plywood, MDF, veneer, OSB, particle boards, plasterboards.

- Packages are covered on 6 sides, with no need for straps, corners, or side covers.

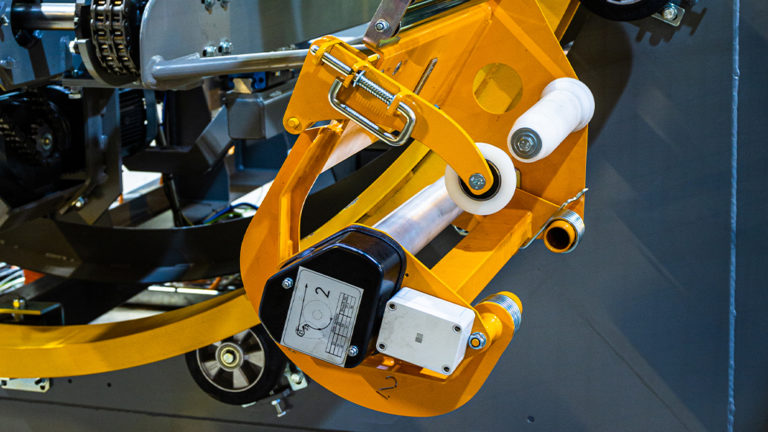

- Can be equipped with feeding and storing conveyors, scales, automatic labeling, RFID identification, and many other options.

- Optional labeling unit automatizes the labeling and keeps labels under the film.

- Wrapping film is 100 % recyclable.

Do you want to take your board packaging line to the next level? Contact us and let’s discuss what is the best solution for you.

Cross Wrap machines

Solutions for board manufacturers.

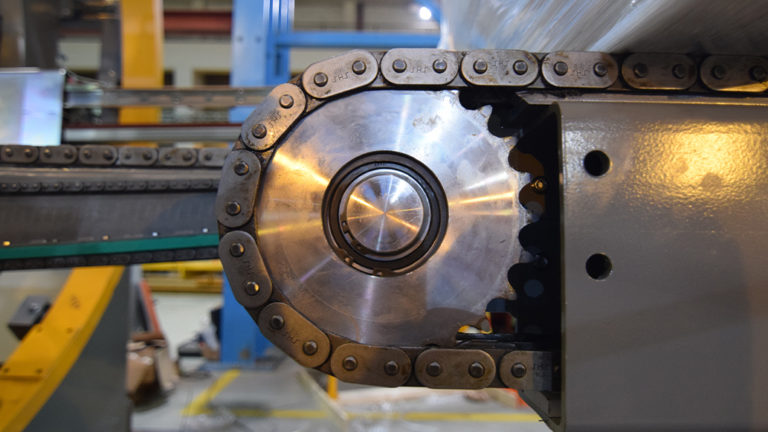

CW Packaging line

All-sides-covered protection for extreme handling and transport conditions.

Wood board packaging references

Need a customized Cross Wrap solution?

Cross Wrap machines can be tailored to your specific needs. Contact us today for more info.