Why Choose Cross Wrap?

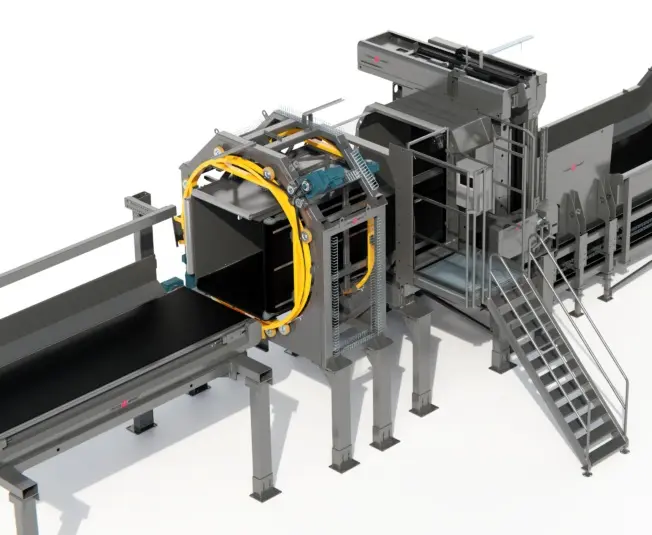

Cross Wrap Oy is a Finnish company specializing in automated bale handling and material flow solutions for the global recycling, waste, and industrial sectors.

With over 650 installations in more than 65 countries, Cross Wrap is known for its innovative bale dewiring, crosswrapping, and opening machines, designed to improve safety, efficiency, and sustainability in material processing.

Cross Wrap was founded in 1994. Today, we are part of Saalasti Group, sharing a commitment to clean technology and durable engineering. Cross Wrap’s mission is to enable cleaner, safer, and more efficient material flows, supporting customers across plastics, paper, board, waste, and fuel processing industries.