Upgrades & Modernizations

Long-term reliability, efficiency, and support.

Long-term reliability, efficiency, and support.

With more than 30 years of experience and a focus on customer needs, Cross Wrap helps you get the most out of your machines throughout their lifecycle. Our upgrade and modernization keep your equipment safe, efficient, and productive – ensuring that your investment continues to deliver value year after year.

Whether it’s updated programming, mechanical improvements, or safety enhancements, every upgrade is tailored to your specific operations. Our goal is to keep your machine running reliably while helping you reduce downtime, increase productivity, and extend its lifetime.

Upgrade your Bale Dewiring machine with side cutting (from front cutter), it will make wire cutting faster and operations more reliable.

Ensure reliable operations in dusty, dirty or otherwise challenging environments. Encoders and linear position sensors measure the movement of the machine instead of relying on optical sight sensors.

Upgrade your Cross Wrap Bale Wrapper to run together with any two-ram baler as a Direct Wrapping machine. We provide the mechanical and operating system upgrades that turn your CW 2200 into a CW Direct. This upgrade removes the need to use baling ties as the Direct Wrapper can wrap the bales directly from the baler and without the need for additional bale tying.

Fits with Bale Dewiring. Automatically flips bales for horizontal wire alignment.

Makes your material flow loose, and steady without breaking material, such as PET bottles.

The Bale stacker automatically lifts and stacks two wrapped bales for easier handling and storage.

Bale turning unit makes it possible to handle both horizontal and cross-wired bales with one machine.

Maintains a tidy and safe work environment by collecting and redirecting any loose material around the line.

Crushes the removed metal coils. This brings your storing capacity to the next level.

Custom-built conveyors provide reliable material flow between material processing stages.

Alerts the operator if the film breaks or runs out. Film watch makes the operation smooth and continuous.

Print automatically labels to each bale directly at the wrapping line.

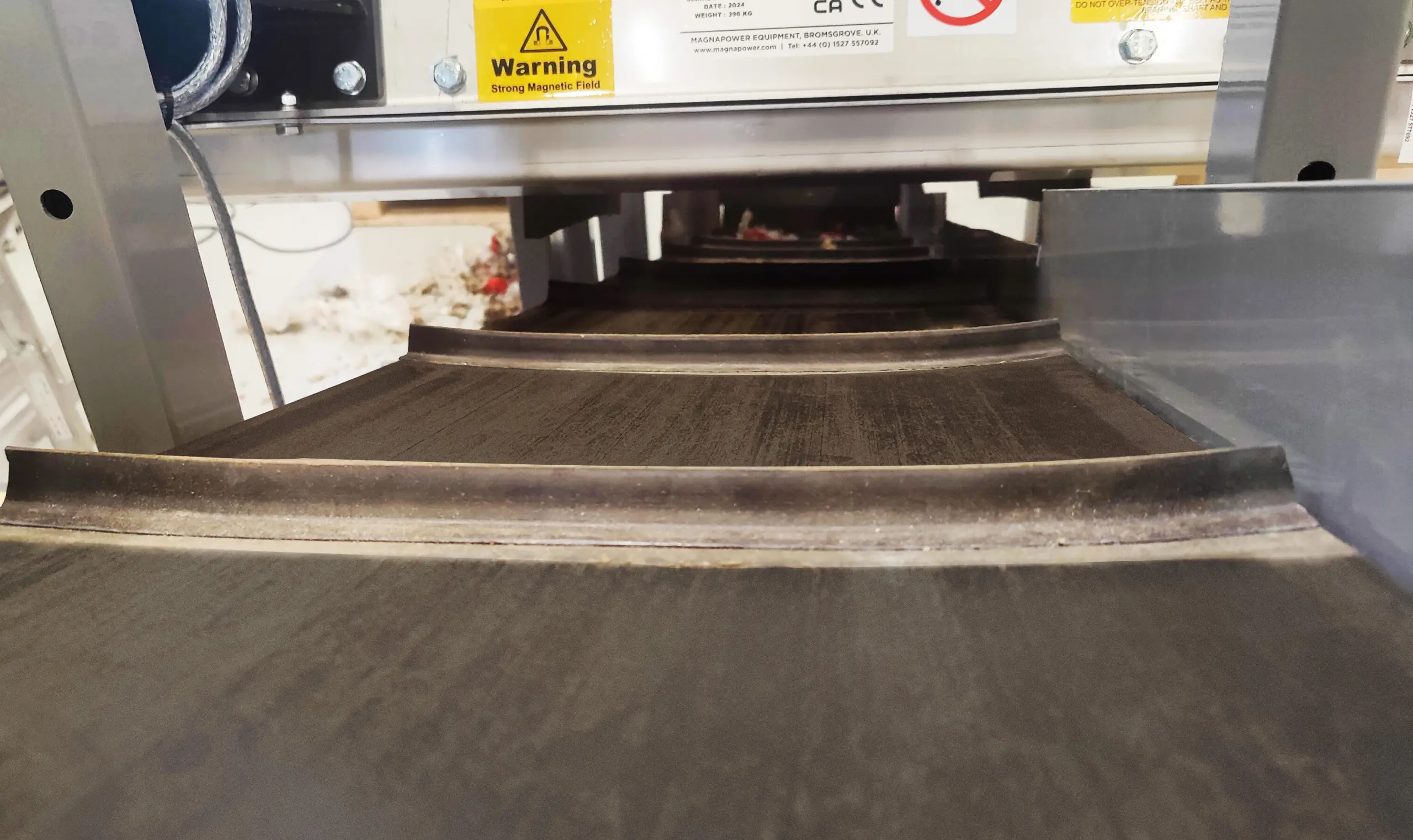

Separates efficiently ferromagnetic metal from shredded material in the wire shredding process.

Helps to create even stronger bales while lowering wrapping film consumption.

Integrates an automatic scale directly into the line, and records bale or package weights.

Below you will find the most popular and valuable upgrades by machine listed. If you have specific needs and can’t find below what you are looking for, contact us – we’ll recommend the best solution. Turnkey packages with all necessary software and manual updates are also available.

Let us know how we can help – our team will be in touch shortly.