Cross Wrap machinery – Robust, reliable, durable

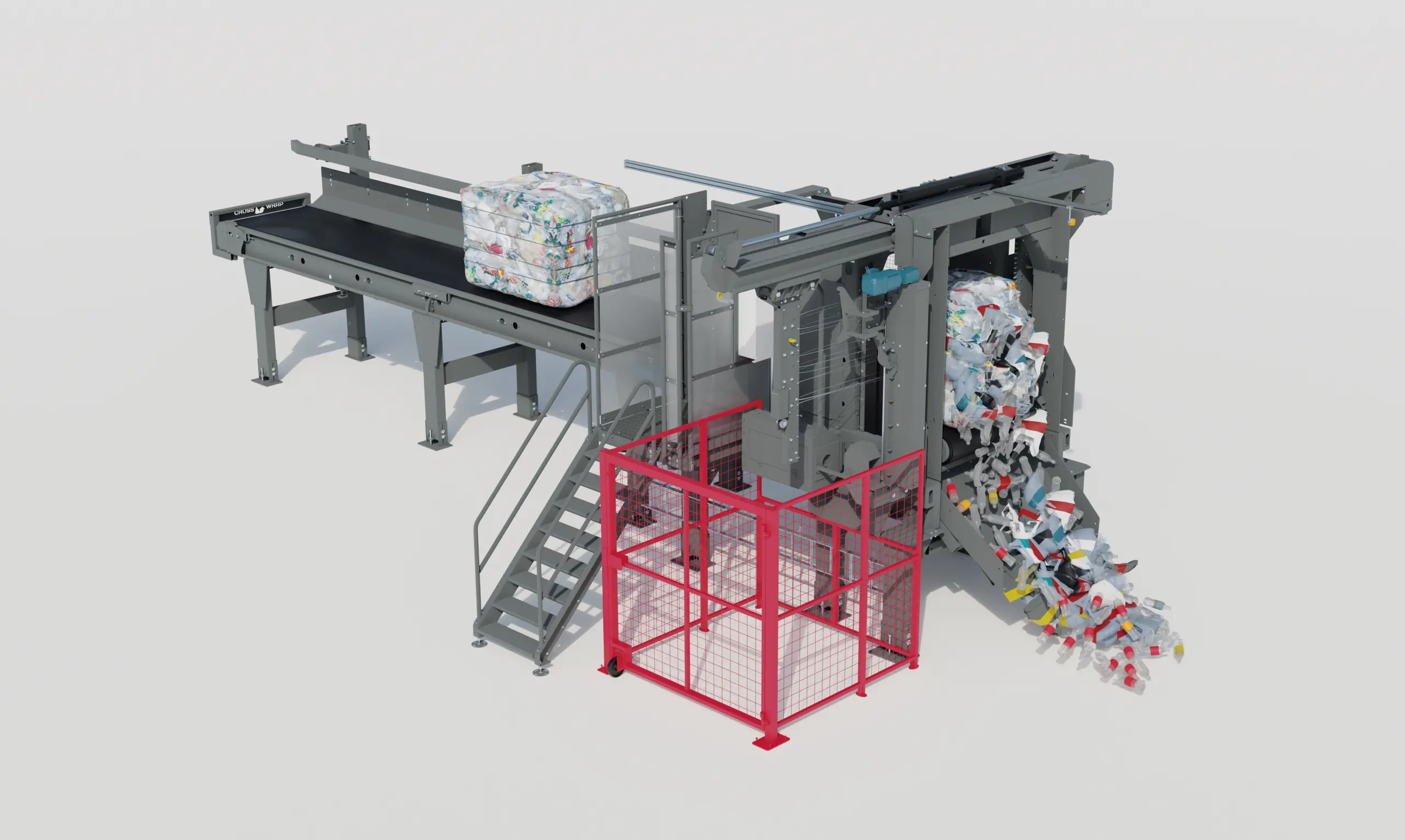

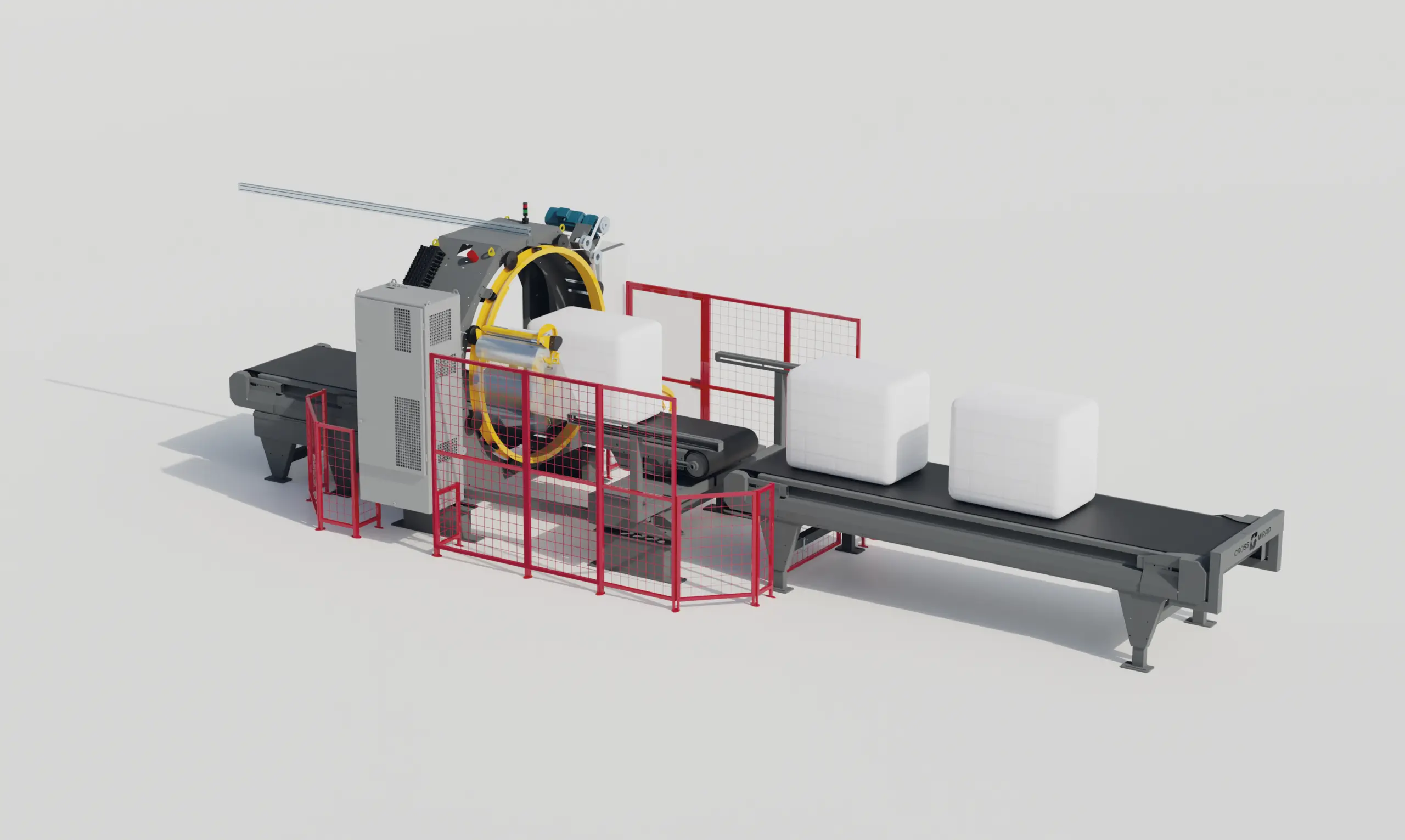

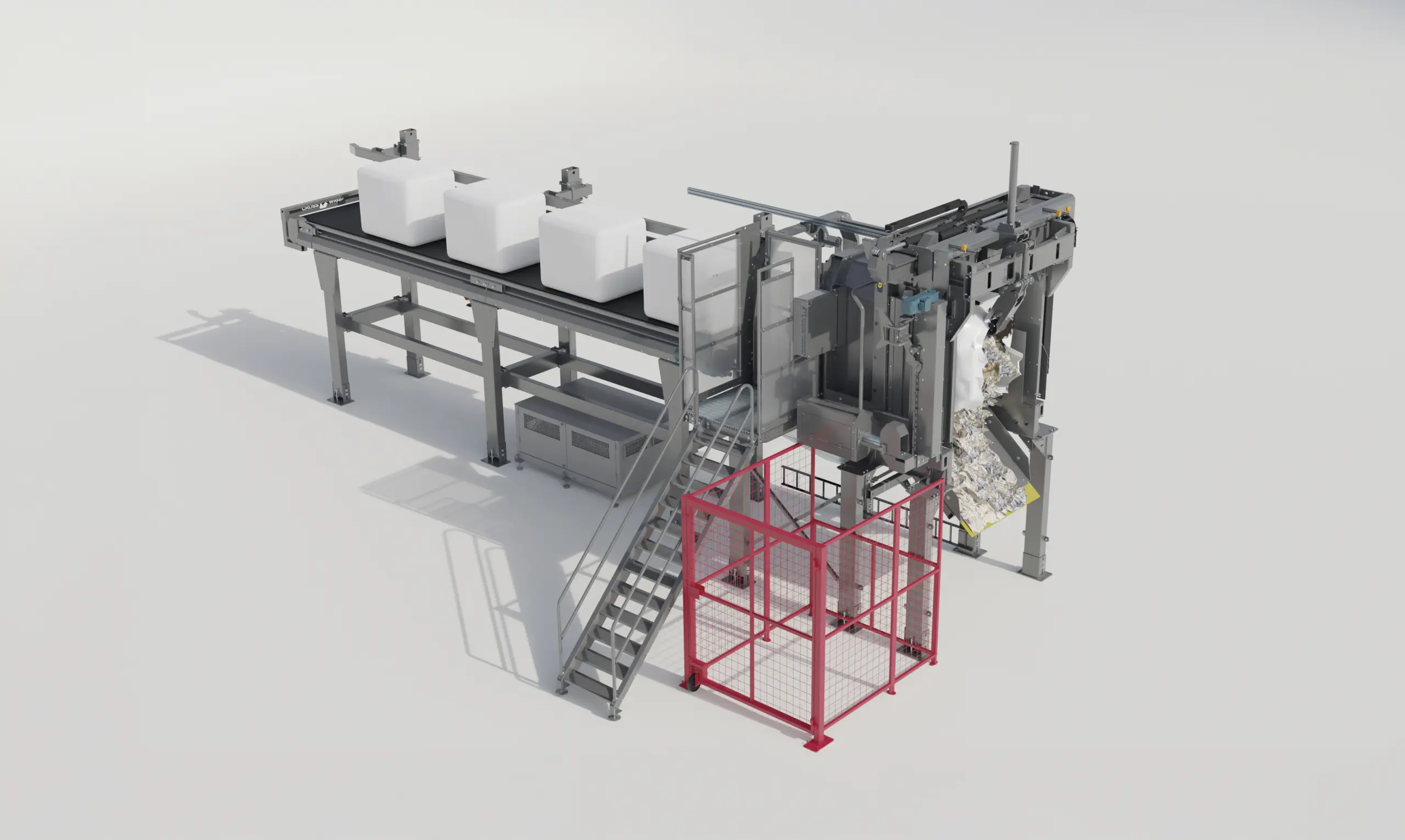

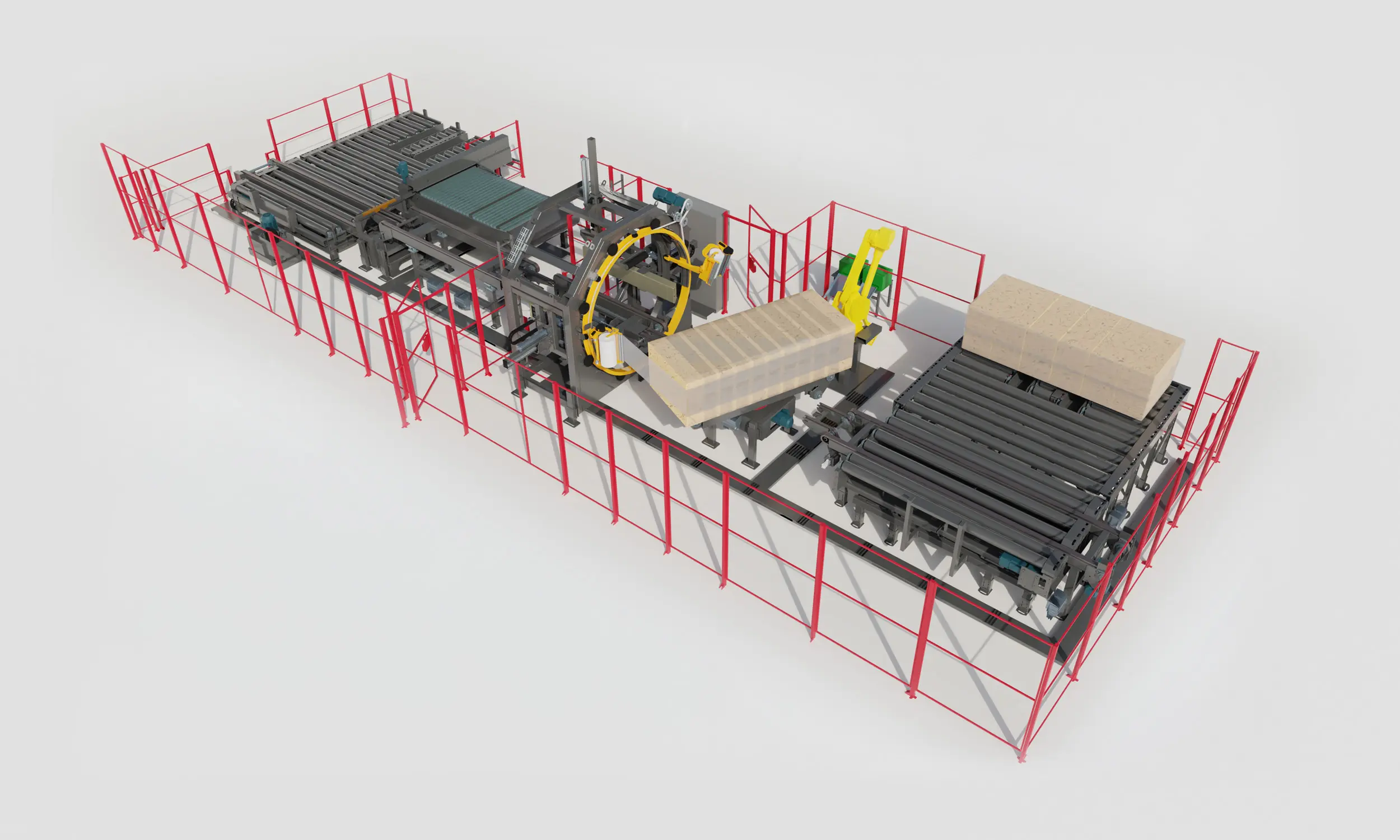

Cross Wrap machinery has become the industry standard for bale wrapping and bale dewiring. Our unique crosswrapping method is trusted by waste and waste-to-energy industry leaders worldwide, while our dewiring technology is setting the global benchmark for reliable wire removal among plastic and paper recyclers.