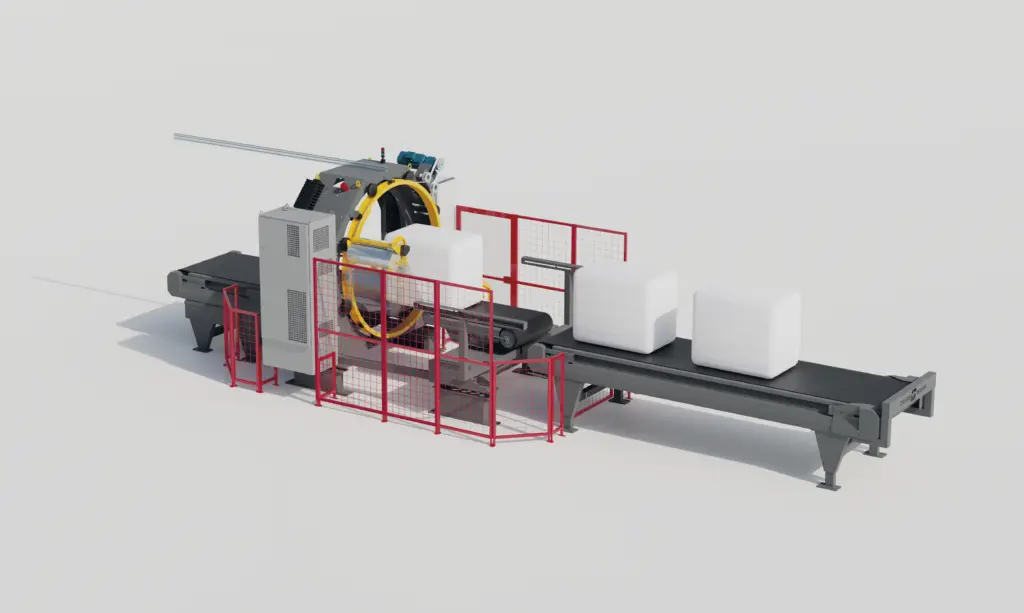

We offer a full portfolio of machines that cover the entire bale handling process from automatic bale wrapping to automatic bale opening. Each Cross Wrap machine and handling method can operate as a stand-alone solution or be integrated into your existing production line.

With a long history of working with all major baler brands, Cross Wrap ensures you get the most out of any baler you operate or plan to purchase. Our square bale wrappers provide unmatched protection for waste-to-energy materials, safeguarding them from moisture while minimizing leakage and litter. As a result, wrapped bales can be safely stored outdoors and withstand transport and multiple handling phases with ease.

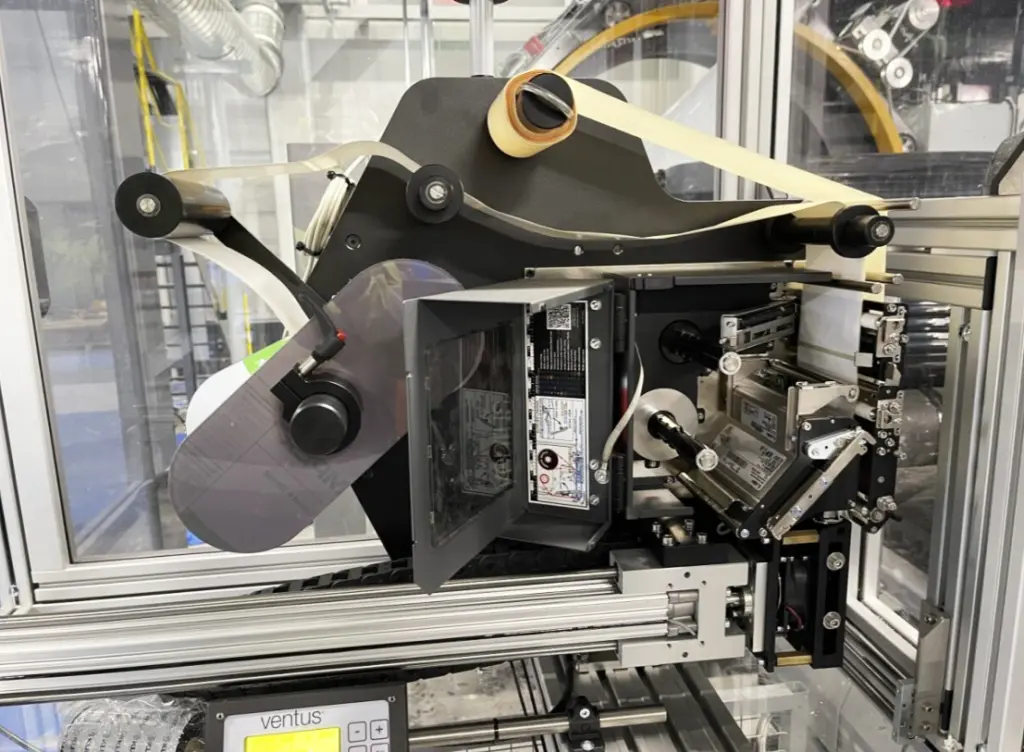

Our crosswrapping method also helps optimize film consumption, allowing customers to choose the most suitable wrapping solution for their specific needs.

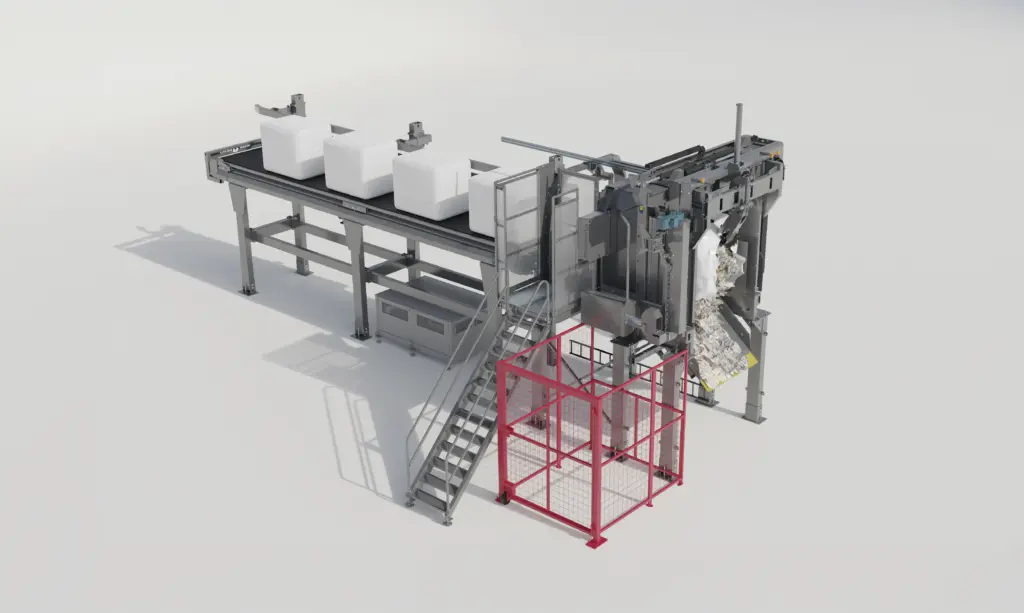

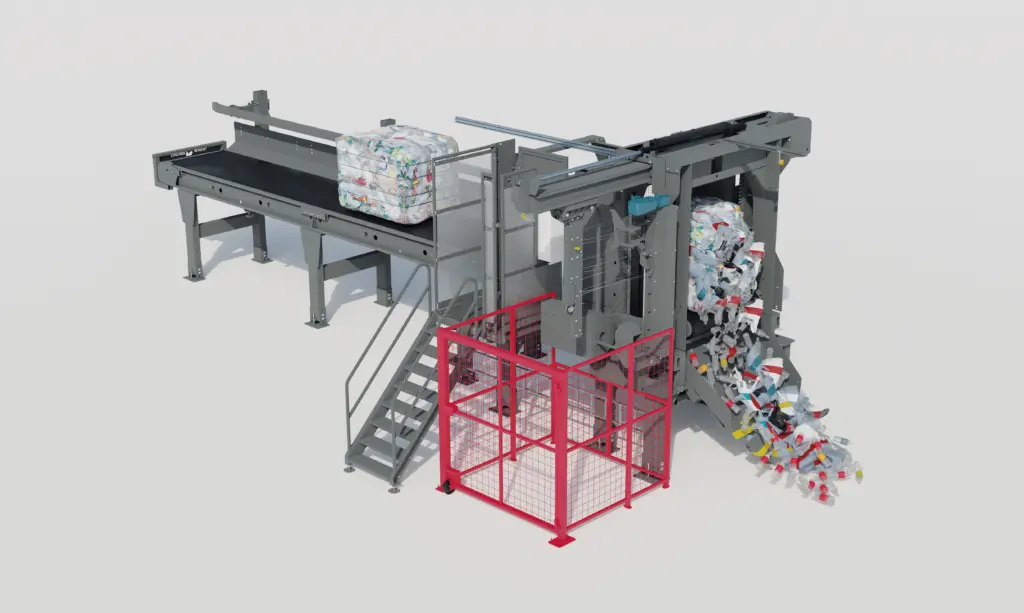

When it’s time to feed the alternative fuel bales to waste-to-energy plants, incinerators, or cement manufacturing processes, our automatic bale openers provide the most efficient and clean method. The process keeps plastic film and metal wires out of the material flow, preventing unnecessary maintenance, machine wear, and costly downtime. This results in better fuel quality and a smaller environmental footprint.

In operations involving shredding, shredder blades last longer since bale wires are removed before the material enters the process.