Blog

Cross Wrap solutions for efficient alternative fuel handling

Solutions for efficient alternative fuel handling

Many industries are constantly moving towards more sustainable and environmentally friendly operations. Green energy, circular economy, and low carbon footprint are becoming household terms when companies are determining and updating their operations. For many businesses, these initiatives mean turning waste into energy or shifting energy sources towards alternative fuels.

Waste-to-energy is one of the biggest customer sectors for Cross Wrap. This includes MRFs, waste fuel manufacturers and traders, waste-to-energy plants, and cement kilns. Due to the ongoing instability in global politics and markets, the waste industry is also facing challenges. Prices in alternative fuels, like SRF and RDF, have experienced more volatility due to lower waste intake and steeply increasing transportation costs.

In this blog, we reveal how Cross Wrap’s vast experience in expert solutions in WTE can help companies to better endure changes in the alternative fuel market. Alternative fuel bale wrapping can ease transportation, storage, and maintaining high material quality.

Decades of Cross Wrap solutions for WTE

We at Cross Wrap have decades of experience in manufacturing automatic bale wrappers and bale openers for various industries. The Cross Wrap bale wrapping method has become the industry standard in wrapping waste and waste fuel material bales, like RDF and SRF. Our standing has been especially strong in the waste-to-energy business.

Wrapped alternative fuel bales can be safely stored outside without odors, leachate, or fire risk

Most of the todays over operating Cross Wrap machines are used in the waste-to-energy industry, and the patented cross wrapping method has gained a status as the industry´s leading way of wrapping baled waste materials.

The Cross Wrap 2200 Bale Wrapper helps to maintain the alternative fuel’s calorific value. The airtight cross wrapped package doesn’t let oxygen inside the package, which prevents the baled material from being composted. This keeps the fuel’s calorific value as high as it was when baled, maintaining the quality of the raw materials. The plastic wrap keeps any moisture away from the baled fuel material, such as RDF or SRF. It also prevents combustion during transporting or storing and reduces the risk of fire.

These above-mentioned benefits keep the stored fuel in good condition. As the alternative fuel market is currently quite unstable in terms of waste intake and material prices, many companies stock up in RDF or SRF bales to avoid challenges related to changes in supply. Safe and efficient storage is essential for stock management.

The CW 2200 Bale Wrapper has become the most used machine in the alternative fuel and waste bale wrapping industry.

Efficient fuel handling concept by Cross Wrap

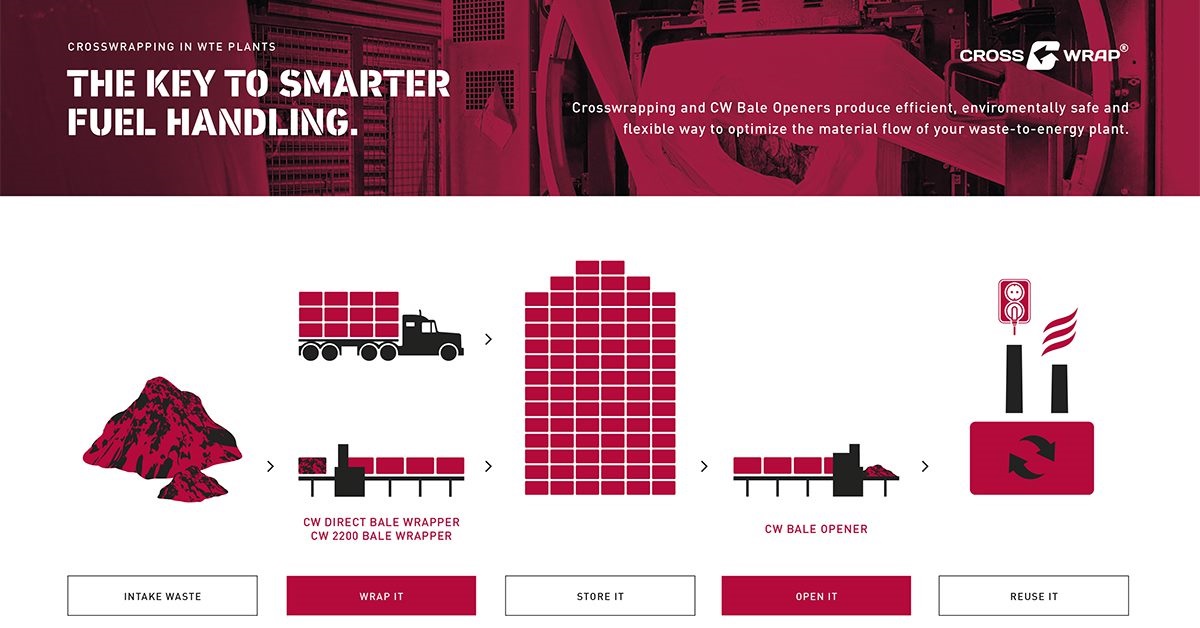

Cross Wrap has created a concept for alternative fuel wrapping and baled alternative fuel lifecycle. The WTE concept is developed to generate operational benefits for alternative fuel users and manufacturers.

The Cross Wrap WTE concept focuses on maintaining good material and operational quality throughout fuel wrapping, transport, and storing operations. As the fuel bales are cross wrapped, the material quality remains unchanged. This concept reveals also other beneficial factors deriving from the wrapping.

Cross Wrap´s WTE method provides an efficient way to handle and store alternative fuels

One of the biggest benefits of wrapping is that the baled and wrapped material can be easily transported and stored. The cross wrapped square bale form is the most efficient logistical shape to be transported, and the balers that produce square bales are the most common industrial balers around the world. Also, the bale densities and weights are maximized when using industrial channel- or two-ram balers. As transportation costs are currently on the rise, material handling efficiency is integral. As square bales are denser than round bales, they can hold more material per m³. By transporting more material per container, the transportation costs of RDF or SRF remain more competitive.

Read more: How square bales differ from round bales?

By cross wrapping the bale structure and content are secured, and the bale handling is safe and clean. Wrapped bales can be safely stacked and stored outside, which helps to minimize the storage expenses and the storage footprint. This enables the possibility to have efficient and safe fuel buffer storage with minimum costs and minimum effects on the fuel material. These storage benefits apply to all positions on the fuel materials logistical journey, such as in harbors, manufacturer´s sites, cement mill grounds, or transport company grounds.

Opening wrapped bales with the Cross Wrap Bale Opener

As we at Cross Wrap have been a long-time pioneer in manufacturing automatic bale wrappers, we have also tackled the task of bale opening. For this demanding task, we have engineered the CW Bale Opener, which automatically opens the bale wrap and ties and separates them from the bale content. The machine’s precise operation allows the operator to run their alternative fuel infeed with high capacity and with minimum manual work.

CW Bale Opener is widely used in the alternative fuel industry

Nowadays there are multiple Cross Wrap Bale Openers operating around the world in cement manufacturing facilities and in waste-to-energy plants. There the CW Bale Opener has received positive feedback and brought good results for our customers processes.

We at Cross Wrap want to offer solutions that not only become industry standards, but which will become game-changers in the way they provide more operational efficiency and competitive advantage to our customers.