Increase your SRF and RDF alternative fuel handling efficiency

ALTERNATIVE FUEL SOLUTIONS TO HELP WASTE-TO-ENERGY AND CEMENT INDUSTRIES TO HANDLE FUEL SMARTER

Are you looking for alternative fuel solutions that help you work smarter? Our unique alternative fuel solutions, automatic bale wrapping and bale opening, are a trusted solution and operate in over 60 countries. Cross Wrap alternative fuel technologies increase alternative fuel usage in the waste-to-energy and cement manufacturing industry with increased automation and smart operation models. Over 600 delivered machines globally are proof of Cross Wrap quality.

CW 2200 bale wrapper – the best wrapper for refuse derived fuel bale wrapping

CW 2200 Bale Wrapper is the industry-standard bale wrapping solution in the waste-to-energy business. This Cross Wrap bale wrapper offers the lowest operational cost and the waste-to-energy industry’s highest production rate for refuse derived fuel bale wrapping. When looking for a proven and efficient bale wrapping solution, CW 2200 Bale Wrapper is the number one solution.

CW direct bale wrapper – solid recovered fuel bale wrapping with no wires or ties needed

Cross Wrap Direct Bale Wrapper is the perfect choice when using a 2-ram baler and simplifying your solid recovered fuel bale structure. The CW Direct Bale Wrapper wraps small fraction size bales directly from the baling chamber without the need for bale wires or bale ties. This unique wrapping method saves time and money while improving efficiency and upgrading your recycling plant safety. It also helps to keep the production line operating with minimal littering, which ensures a clean and safe production facility.

All the Cross Wrap bale wrappers are fully automatic, save labor costs and improve working safety. Cross Wrap bale wrappers work seamlessly with all baler brands and waste baler machines.

CW Wrappers offer an impressive 80-ton-per-hour capacity while still running cost-efficiently for smaller capacity operations. Both bale wrappers are proven solutions for wrapping even the most demanding materials, such as municipal solid waste (MSW) or waste-based fuels like RDF or SRF.

WHY CHOOSE CROSS WRAP BALE WRAPPERS FOR ALTERNATIVE FUELS?

- Wrapping helps to maintain the calorific value of alternative fuel

- Wrapped bales are more durable in transportation and handling

- Wrapped alternative fuel bales maintain their shape

- Smaller fire hazard during storage

- Square, wrapped bales improve logistics by saving space

Please accept statistics, marketing cookies to watch this video.

WRAPPING IS A MUST-HAVE FOR COST-EFFECTIVE RDF AND SRF WASTE FUEL TRANSPORTATION

Did you know that Cross Wrap’s alternative fuel solutions make the transportation of SRF and RDF bales easier? By baling and wrapping the SRF and RDF waste fuel bales, the material is packed denser and more fuel fits in a shipping container or in the back of a truck. Wrapped bales are more durable in handling and transportation and can be moved long distances to waste-to-energy plants or cement kilns without a risk of breaking, leaking, or littering. As more alternative fuels used in the cement industry, investing in cost-effective transportation is a must.

The innovative features of cross wrap alternative fuel technologies

Both of the Cross Wrap bale wrappers can be run with 500 mm- or 750 mm-wide films, depending on your operation needs. Additional practical features include cleaning conveyors, opening safety fencing, automatic bale weighing, automatic bale labeling, RFID tagging, and remote control. All Cross Wrap bale wrappers have a 3G, LAN, WLAN modem that allows for easy remote troubleshooting and software changes, ensuring that your bale wrapper always performs at its best. Our customer portal and spare part web shop, Cross Wrap Smart, ensures you have a 24/7 access to your current machine operational, manuals, and spare parts.

CROSS WRAP BALE WRAPPER FEATURES FOR EFFICIENT ALTERNATIVE FUEL HANDLING:

- Customize your machine with special feeding and outfeed conveyors

- Choose from 500 mm or 750 mm wide film

- Add automatic cleaning conveyors to decrease manual cleaning

- Customize your machine with opening safety fencing

- Improve your on-time operation accuracy with automatic bale weighing

- Keep track of your bales with automatic bale labeling or RFID tagging

- Keep your operation flowing with remote control

- Allow easy update and troubleshoot with modem connection

- Create even more rigid bales with optional net wrapping

"What we like the most with our collaboration with Cross Wrap is their reliability”

– Alfredo Vigre, FCC Medio Ambiente, Spain.

Patented bale opener for alternative fuel and cement industry

Cross Wrap’s patented Bale Opener machine is integral part of our alternative fuel solutions. The machine automatically cuts the bale film and bale wires, safely removing them from your alternative fuel bale content.

The machine spools the removed wrapping film and wires into a bundle that is easy to handle and recycle. This unique and automatic machine improves the fraction quality of refuse derived fuel and solid recovered fuel, while making bale handling and opening safer and more efficient.

The CW Bale Opener provides long-lasting reliability and low operating and maintenance costs. Cross Wrap also deliveries CW Wire Cutters for operations where there is only a need for bale wire cutting.

THE BENEFITS OF CROSS WRAP BALE OPENER FOR ALTERNATIVE FUEL TECHNOLOGIES:

- Automate your bale opening with film and tying material removal

- Run your operation flexibly with a system that allows both square and round bale opening

- Become more efficient with fast and reliable bale opening operation

- Keep it simple with an easy-to-use interface and with remote control option

- Just leave it running – You can count on its robust and low maintenance structure

- Save energy – the CW Bale Opener uses less energy than any other method available

- Improve your material fraction by removing the wrap and ties from the bale content

- Choose a wire cutting solution if that is the only operation needed.

High capacity and fast payback for smart alternative fuel solutions

What if you could automatize your material infeed and improve safety and handling, whilst also cutting costs? Our innovative alternative fuel technologies for automatic bale wrapping and bale opening optimizes your alternative fuel manufacturing, usage, and logistical chain.

All Cross Wrap engineered and manufactured alternative fuel bale wrapping and bale opening machines ensure a high 80 tons per hour capacity in processing alternative fuels and waste-based materials. The machines have a fast payback time with long term cost-saving effects. Fully automatic operation minimizes labor costs and tight square bale wrapping ensures most tonnages per m2 in transportation. Our machines are a proven solution in the waste-to-energy sector and when using alternative fuels in the cement manufacturing industry.

“We want to operate with the best possible machinery available such as Cross Wrap,” Simon Little, Powerday, UK.

“By using the CW Bale Opener, our RDF feeding process was simplified, offering more time for general system maintenance and fuel stock management, and optimizing alternative fuel logistics”

– Mr. Hernán Chantiri, InterCement, Argentina.

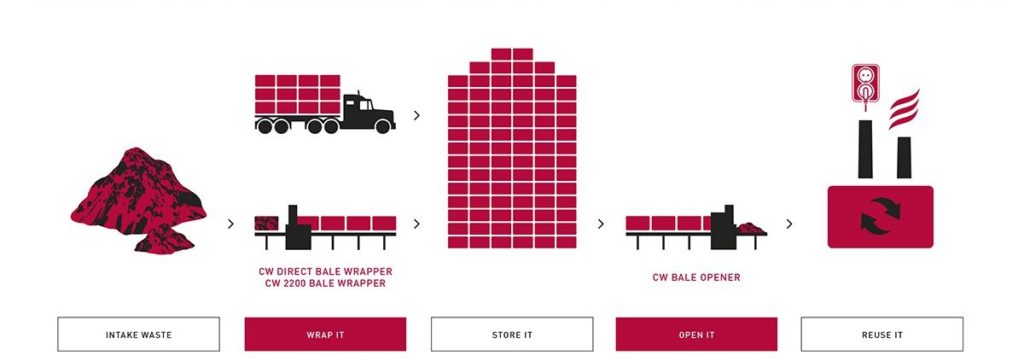

Efficient alternative fuel handling operation combines cross wrap solutions

INTAKE MATERIAL

Loose or baled waste readiness for waste amount fluctuations.

WRAP BALES WITH CW BALE WRAPPER

A clean and effective way to maintain the material’s energy value allows waste intake during low energy demand season and maintenance breaks.

EFFICIENT STORAGE AND TRANSPORT WITH WRAPPED BALES

An environmentally safe and cost-efficient way to store the fuel that allows outdoor storing – saving cost and space of indoor storage. The transporting of Cross Wrapped bales is easy, clean, and cost-effective.

OPEN BALES WITH CW BALE OPENER

Opens the bales automatically – less labor and machinery cost, increased safety – opens automatically rectangular and round bales – separates the ties and film from the baled material.

CROSS WRAP MACHINERY FOR ALTERNATIVE FUELS SECTOR

All Cross Wrap alternative fuel machine innovations are born from our customer’s needs, and our best reference is a large number of satisfied customers. Waste-to-Energy operators, MRF’s, and cement kilns worldwide have included Cross Wrap machines as a part of their choice of high-quality alternative fuel bale handling machinery to increase their operational safety and efficiency and to decrease their operating costs.

Please look at our global references and join the group of companies who have chosen the smartest way to handle alternative fuel. We welcome you aboard the industry-leading group of Cross Wrap’s customers around the world!

PLEASE LOOK AT OUR GLOBAL REFERENCES

ALTERNATIVE FUEL SOLUTIONS REFERENCES:

ARX ARCILLEX, ARGENTINA

Argentinian ARX Arcillex S.A. uses CW 2200 Bale Wrappers for wrapping MSW and RDF. The company has had so positive experiences with the Cross Wrap machine performance that they are most likely to incorporate CW wrappers into their future projects.

FCC MEDIO AMBIENTE, SPAIN

Spain-based FCC Medio Ambiente acquired four Cross Wrap CW 2200 Bale Wrappers to wrap recycled waste refuse material that is destined to dry landfill. The wrappers were installed at three recycling sites Gomecello, Loeches, and El Campello.

MUNICIPALITY OF ROCHA, URUGUAY

Rocha, Uruguay located Deisa operation for baling and wrapping urban solid waste (MSW) does their bale wrapping with Cross Wrap Direct Bale Wrapper. The plant has a 12 tons/hour capacity, and the wrapped bales are destined for balefill.

EUROPRESS-UMWELTTECHNIK GMBH

Germany based Europress-Umwelttechnik GmbH provided their customer with a unique mobile baling and wrapping unit with Cross Wrap Direct Bale Wrapper to bale and wrap artificial mineral fiber.

REPOWER SOUTH

RePower South whose waste-to-energy operation model is new to the US market was supplied with Cross Wrap bale wrappers.

POWERDAY

Privately owned Powerday is one of the largest London based recycling and waste management companies. It has three different sites in the close vicinity of London city center.