Recycling Solutions

Recycling plant machinery for creating smarter recycling solutions

Cost-saving recycling plant machinery for creating smarter recycling solutions

Cross Wrap recycling solutions help industries to work smarter. Cross Wrap’s unique automatic bale wrapping, bale opening, and bale dewiring machines are trusted and operating in more than 60 countries. Cross Wrap recycling plant machinery helps increase recycling plant safety and recycling plant efficiency with increased automation and smart operation models. Over 600 delivered machines globally are proof of Cross Wrap quality.

CW 2200 BALE WRAPPER – LOWEST OPERATIONAL COST, HIGHEST PRODUCTION RATE

CW 2200 Bale Wrapper is the industry-standard bale wrapping solution in the waste-to-energy and recycling business. This highly innovative bale wrapper offers the lowest operational cost and the recycling industry’s highest production rate. When looking for a proven and efficient bale wrapping solution, CW 2200 Bale Wrapper is the number one solution.

CW DIRECT BALE WRAPPER – NO WIRES OR TIES NEEDED, SAVE MONEY AND RESOURCES

Cross Wrap Direct Bale Wrapper is the perfect choice when using a 2-ram baler and simplifying your bale structure. CW Direct Bale Wrapper wraps the bales directly from the balers baling chamber without the need for baling wires. This unique wrapping method helps you save time and money while improving efficiency and upgrading your recycling plant safety.

All the Cross Wrap bale wrappers are fully automatic, saving labor costs and improving working safety. Cross Wrap bale wrappers and Cross Wrap recycling plant equipment work seamlessly with all baler brands and waste baler machines. Both CW Wrappers offer an impressive 80-ton-per-hour capacity while still running cost-efficiently also for smaller capacity operations.

Read more

CROSS WRAP BALE WRAPPERS

THE MODELS OF CROSS WRAP BALE WRAPPERS

SORPA, Iceland

Read more

Fortress Recycling, UK

Read more

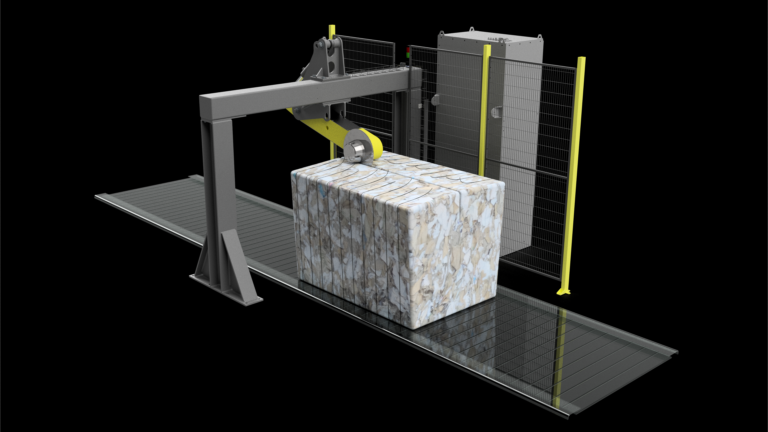

Bale Slice Breaker

Read more

Bale Handling Devices

Read more

Cross Dewiring Unit

Read more

Chain belt & chain lamella conveyors

Read more

CW 2200 Bale Wrapper

Safe, efficient, and cost-effective bale wrapping – the industry standard.

BEST PRACTICES TO INCREASE YOUR PRODUCTIVITY WITH CROSS WRAP RECYCLING SOLUTIONS

Both Cross Wrap bale wrappers can be run with 500 mm- or 750 mm-wide films, depending on your operation needs. Additional practical features include cleaning conveyors, opening safety fencing, automatic bale weighing, automatic bale labeling, RFID tagging, and remote control. All Cross Wrap bale wrappers have a 3G, LAN, WLAN modem that allows for easy remote troubleshooting and software changes, ensuring that your bale wrapper always performs at its best.

- Cross Wrap’s best practices to optimize recycling plant safety and efficiency:

- Customize your machine with special feeding and outfeed conveyors

- Choose from 500 mm or 750 mm wide film

- Add automatic cleaning conveyors to decrease manual cleaning

- Customize your machine with opening safety fencing

- Improve your on-time operation accuracy with automatic bale weighing

- Automate your bale tagging with automatic bale labeling or RFID tagging

- Keep your operation flowing with remote control

- Allow easy update and troubleshoot with modem connection

- Create even more rigid bales with optional net wrapping

SMART BALE DEWIRING FOR EFFICIENT RECYCLING SOLUTIONS

The unique CW Dewiring machine automatically cuts and removes steel wires from all forms of recycled material bales. This innovative bale dewiring method improves recycling plant safety, minimizes the need for manual operation, and guarantees the steady flow of high-quality recycled materials for processing without steel wire fragments.

For boosting your operational efficiency and recycling rate even higher, the CW Dewiring machine coils the removed bale wires automatically into small, tight bundles that are easy to handle and to recycle. The CW Dewiring machine’s additional features are customizable in-feed and out-feed conveyors, and it can dewire multiple bale sizes with various materials and ties.

“The CW Dewiring machine is also nominated for the prestigious Plastics Recycling Awards Europe 2020 for CW Dewiring machine in Recycling Plant Machinery Innovation of the Year category.”

The advantages of Cross Wrap Dewiring machine:

- Increase your operating safety by automating bale dewiring

- Lower your operational costs with the fully automatic dewiring operation

- Improve your recycled material quality with efficient and automatic bale wire removal

- Handle your bales and removed bale wires more efficiently

- Count on the pro – built by professionals for professionals

- Lower your recycling line maintenance costs with smart bale Dewiring with unmatched reliability

PATENTED BALE OPENING METHOD FOR WASTE-TO-ENERGY AND CEMENT INDUSTRY

Cross Wrap’s patented Bale Opener machine automatically cuts the bale film and bale wires, safely removing them from your bale content and process material stream. The Cross Wrap Bale Opener spools the removed wrapping film and wires into a bundle that is easy to handle and recycle. This unique and automatic machine improves material fraction quality while making bale handling and opening safer and more efficient. The CW Bale Opener provides long-lasting reliability and low operating and maintenance costs. Cross Wrap also deliveries CW Wire Cutters for operations where there is only a need for bale wire cutting.

The advantages of Cross Wrap solutions for waste-to-energy and cement industry:

- Automate your bale opening with film and tying material removal

- Run your operation flexibly with a system that allows both square and round bale opening

- Become more efficient with fast and reliable bale opening operation

- Keep it simple with an easy-to-use interface and with remote control option

- Just leave it running – You can count on its robust and low maintenance structure

- Improve your material fraction by removing the wrap and ties from the bale content

- Choose a wire cutting solution if that is the only operation needed.

Recycling solutions

RECYCLING SOLUTIONS THAT MAKE A GREAT DIFFERENCE

All our recycling machine innovations are born from our customer’s needs, and our best reference is a large number of satisfied customers. Recyclers worldwide include Cross Wrap machinery as a part of their choice of high-quality recycling plant machinery to increase the recycling plant safety and efficiency.

Look at our global references and join the group of those who have chosen the smarter way. We welcome you aboard the industry-leading group of Cross Wrap’s customers around the world!

Solution References

Solution References

LafargeHolcim, Spain

One of the biggest benefits of the CW Bale Opener is its operation, which opens both the square and round bales. For this it is the perfect choice for LafargeHolcim.

Need a customized Cross Wrap solution?

Cross Wrap machines can be tailored to your specific needs. Contact us today for more info.