Industrial Paper Recycling Solutions.

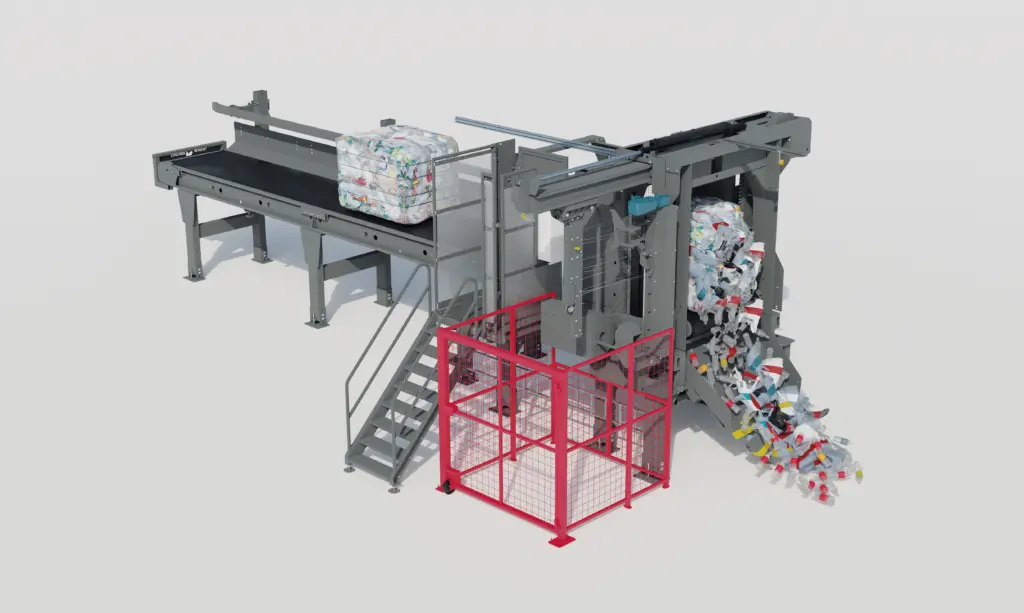

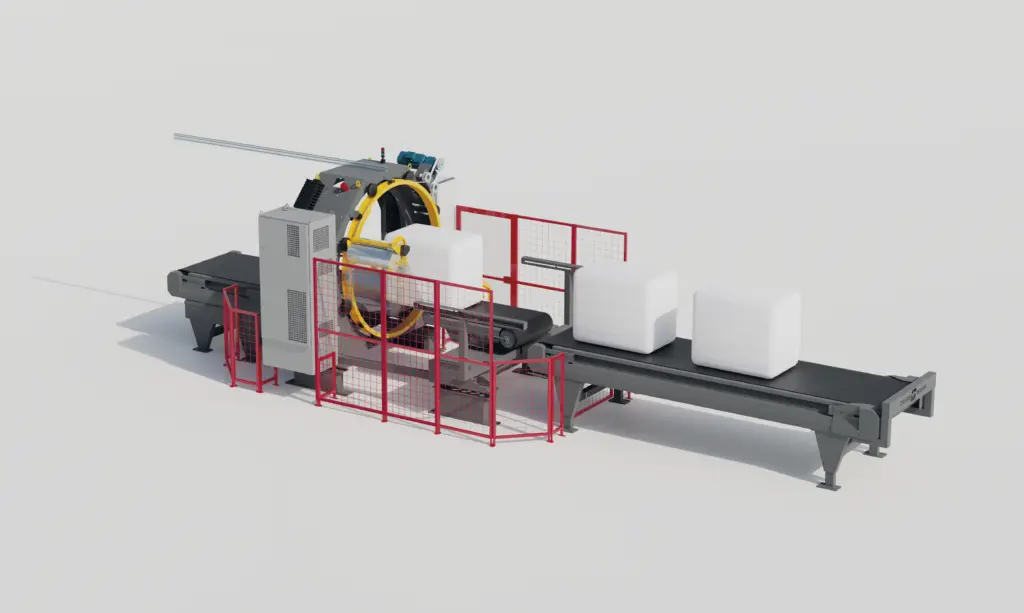

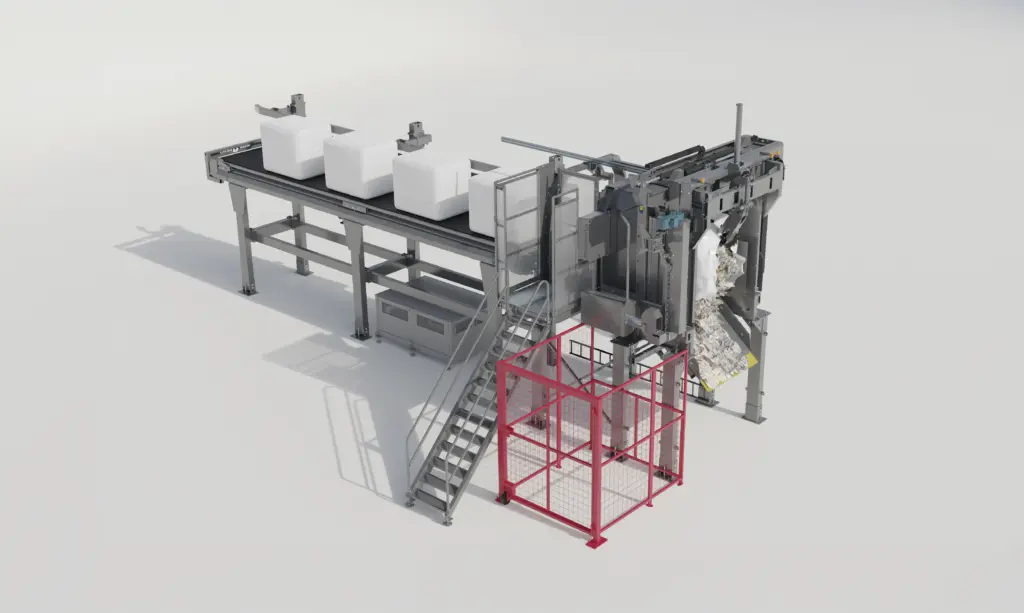

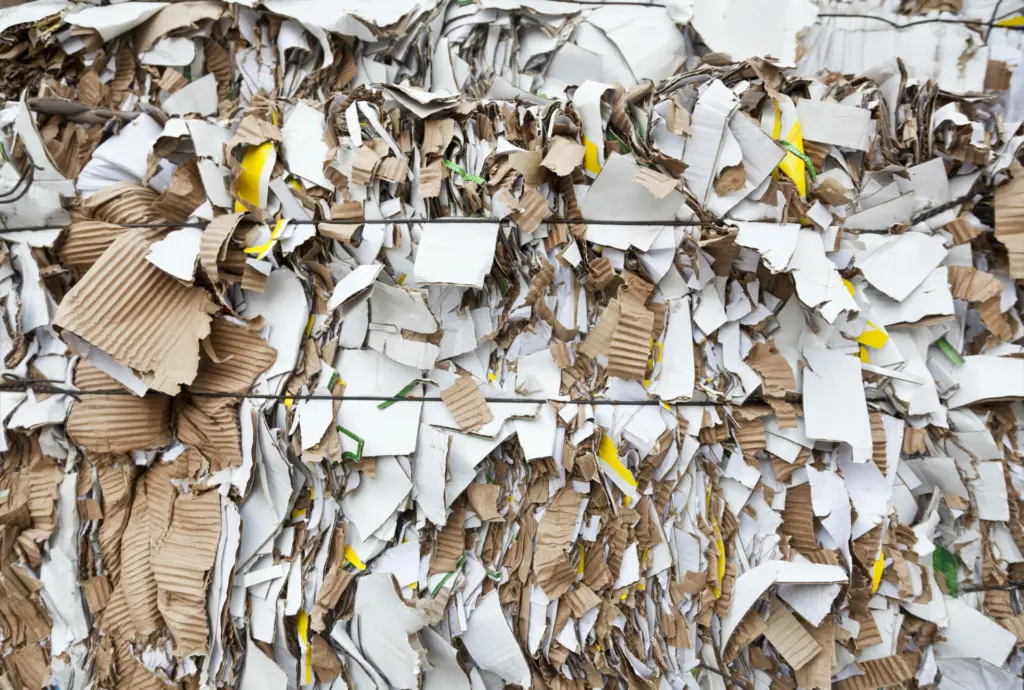

Handling OCC and recovered paper bales comes with one big challenge: bale wires. Left unchecked, they cause ragger rope build-up, pulper damage, and costly downtime. Cross Wrap machines are designed to automate wire removal and bale opening, keeping your line safe, steady, and efficient.

With over 100 dewiring machines and cutters delivered globally, including leading paper recyclers, we bring proven experience to every mill.