References

Svensk Plaståtervinning, Sweden

MAKING PLASTIC RECYCLING MORE EFFICIENT WITH COLLABORATION

The cooperation with Cross Wrap [in the Coil shredder prototype project] has been great. Good meeting structure and a good way of solving the problem from start to finish, says Mr. Anders Carlberg, production technician at Svensk Plaståtervinning.

PLASTIC AND METAL MIXED

Svensk Plaståtervinning (Swedish Plastic Recycling) is a modern plastic recycling facility located in Motala, Sweden. The facility is the largest and most efficient plant of plastic recycling in the world and it has the capacity to handle all plastic packaging from all Swedish households. The company’s vision is that all plastic packaging in the country should be recycled and made into new products. The newly opened Site Zero is a massive, automated facility that contains kilometers of conveyor lines.

Svensk Plaståtervinning dewires their plastic material bales in two operating lines. The metal wires can be recycled and in the best case they provide extra income for the facility. But the metal output has to be clean, which is not always the case with wire coils.

Mr. Anders Carlberg, production technician at Svensk Plaståtervinning says that the coil material is taking more room in storing and shipping containers because of the plastic material remaining in the coils. “We ship one third of a container because the coils and plastic are so voluminous”, Carlberg says.

He wanted to tackle this problem and increase the efficiency of the facility, and it was time to investigate different options. Carlberg tells that shredders in the market weren’t the right fit for their facility. “We found some shredders that could have worked but we should have had a steering and a protection system. That would have been too complicated for us to fix at a good price and reasonable effort”.

Then Carlberg contacted Cross Wrap because of earlier experience with the company. In 2017, a CW Dewiring machine was installed in the facility and a second one a bit later.

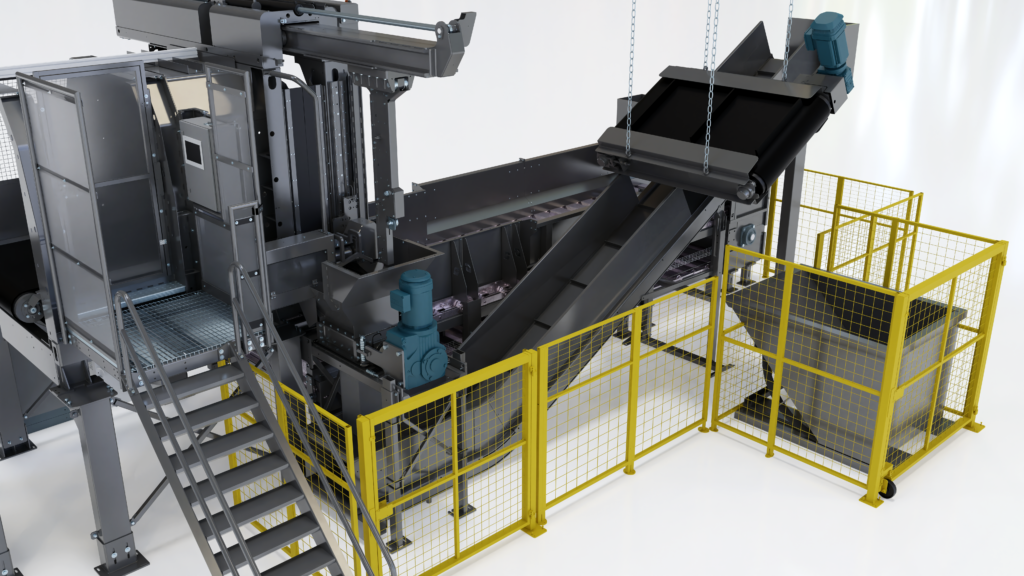

The CW Coil Shredder is small and compact, and specifically designed to work alongside our Dewiring machine

COIL SHREDDER SAVES SPACE IN SHIPPING

Svensk plaståtervinning and Cross Wrap started to tackle the problem together in a prototype project. The finished product is the CW Coil shredder. It shreds the coil into pieces that are easily separated from the plastic material with a magnet. The Coil shredder is a turnkey solution for separating coils and plastic material.

“The shredder works very well and we have increased the amount of metal we are shipping out from 3 tons to 6 tons per container.”

Although, in Svensk Plaståtervinning’s case they chose a Coil shredder without the metal separating. That part is already taken care of later in their plastic recycling line, when a magnetic conveyor located above the material conveyor collects the metal. Cross Wrap’s Coil shredder makes it possible to have a clean metal output.

According to Carlberg, the installation and adjustments of the new machine went smoothly. “I think everything was done in two or three days, and after that some time was needed for the adjustments”, Carlberg recalls. “The shredder works very well and we have increased the amount of metal in the container we are shipping out from 3 tons to 6 tons”, he adds.

The Coil shredder also works smoothly with the other machinery and is operated from the Dewiring machine’s control panel.

The CW Coil shredder is a product of cooperation between Cross Wrap and Svensk plaståtervinning

FINDING SOLUTIONS TOGETHER

Mr. Aki Paananen, Chief operating officer at Cross Wrap says collaboration in product research and development is a win-win situation for both Cross Wrap and the client. Even though tailored solutions are not offered, testing prototypes with clients in real facilities speeds up the product research and development process significantly and enables Cross Wrap to answer clients’ needs even better.

“We appreciate companies that want to have this kind of collaboration with us. After all, they know their processes and needs best. New ideas and innovation are needed all the time because professional plastic recycling is a relatively new industry. We listen to our clients and act fast when needed”, Paananen says.

IN A NUTSHELL

- Company: Svensk Plaståtervinning

- Locations: Motala Business Park, Sweden

- Materials: PP, HDPE, LDPE, PET tray, PET bottles (coloured and transparent), PP film, EPS, PS, PVC, two grades of Polyolefin mix, metal and non-plastic waste

- Site Zero receiving capacity: 200,000 tons of plastic packaging per year

- CW machines: 2 x Dewiring machine, Coil shredder