Blog

CW Packaging line is a smart solution for board manufacturers

A smart solution for board manufacturers

We at Cross Wrap know all about the struggles of the board industry: long shipping distances, high labor costs, and choosing the correct packaging that ensures that the valuable end product is not damaged during transportation or storage period.

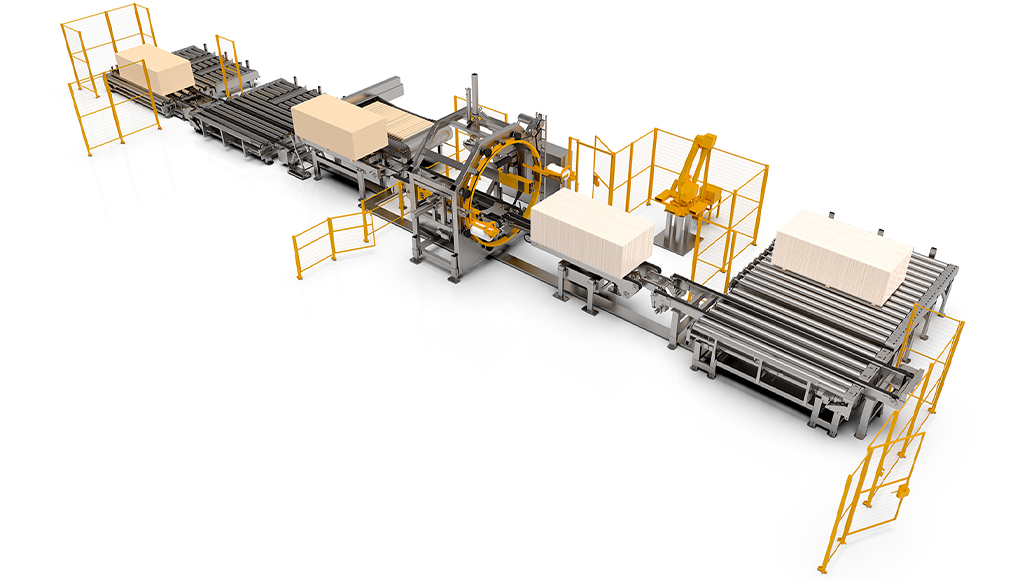

Our CW Packaging line is a smart solution designed for these needs in the board industry. We are experienced in packaging various sizes and types of boards, including plywood, veneer, and gypsum boards. Read on to learn more about the benefits of board packaging line!

Cut costs with automation

The automatic board packaging line helps you to reduce the need for manual labor in packaging boards. It lowers the labor costs and helps to redirect employees to other tasks. Compared to manual or semi-automatic packaging, completely automatic board wrapping is faster and more efficient. The machine wraps the board stacks from all six sides, first vertically, then horizontally, and then vertically again. This produces high-quality packages quickly.

In addition to labor costs, energy efficiency has become a key decision-making criterion for the future of many businesses and operations. The completely electrical board packaging line is energy efficient and safe solution for packaging wood-based boards. Automation makes the process more time-efficient!

Read next: Behind the scenes: CW Packaging line in the making

Wrapped board stacks are easy to handle and transport

Better board shipping and handling

Many companies ship their end products far from their facilities – logistics is a key operational component for many wood board industry manufacturers. To ensure that the boards reach their destination unharmed, good packaging is important.

With the CW board packaging line, the board stacks are wrapped neatly in stretch film – according to our experiences, LLDPE wrapping film provides the best results. Our automatic wrapping unit ensures that the film is placed in the corners of the board stacks, which require the most coverage to prevent tears in the packaging. This solution in automation also makes sure that the wrapping film usage is optimized and no film is wasted. Wrapping is a gentle solution, that does not harm the boards.

Tight, moisture-proof wrapping prevents moisture and dirt from getting into the boards during shipping, handing or storage. The package structure is strong, and the packaged materials remain good shape, even if they would need to be stored for long time. In addition, the packaging is durable and prevents the stacks from breaking apart at any stage of the logistics chain. An additional feature of the CW Packaging line, an automatic bottom skid feeder, keeps the bottom of the stack elevated, which make the packages easier to handle and store.

Store the boards on display!

Wrapping produces a sleek package, which is also practical

With the CW board packaging line, product packages are clean and neat. The board packaging line wraps the board stacks on all six sides, using only one packaging material. A seaming unit eliminates the wrapping film ‘tails’ on the ready packages. When the wrapping process is finished, the end of the film is sealed to the package with heat. This leaves no film hanging, making the package neater.

The packages are sleek and nice to look at – thus they can gladly be stored on display. Thanks to the durable and moisture-proof packaging, the board stacks can be stored both inside and outside without any worries of damage to the end product.

Adding an optional labelling robot to the packaging line is another way to ensure that the packages look good – and can be easily recognized and tracked. Good labelling shows your brand, the product name, and helps to keep track of batch numbers. With the board packaging line, your product label will always look good. The robot places the label in between the wrapping film, which keeps the label in place and protects it from moisture.

If you wonder about the sustainability of the packaging option, worry not! The packaging is easily recyclable. The wrapping film can be sorted with plastic, and thanks to the labelling robot which places the paper labels under the film, the label can be separated easily and sorted accordingly as well.

Wrap your boards with Cross Wrap

Could the CW Packaging line be the solution to suit your needs?

Rely on our expertise in board packaging! We are happy to serve your needs in board packaging and find a customized solution that fits your production and facility needs.

- Reduce labor and energy costs and optimize the use of packaging materials with automated board wrapping

- Customize the packaging line according to your needs with an automated bottom skid feeder, a labelling robot or a seaming unit.

- Keep moisture and dirt away during shipping, handling, and storage to deliver the best possible quality boards

Could the CW Packaging line be the solution to suit your needs? Contact us at sales@crosswrap.com