Blog

Flexible, customer-oriented and innovative – that’s Cross Wrap

Flexible, customer-oriented and innovative – that’s Cross Wrap

“Ideas for new solutions surface in direct contact with our customers. While visiting facilities around the world, we identify potential obstacles, discuss with our customers before producing something new and alway provide innovative adjustments at the installation stage,” Cross Wrap’s CCO Mirja Yli-Erkkilä describes our innovation process.

Since the founding of Cross Wrap, our business has been based on flexibility and a can-do attitude. We are problem solvers and meet our clients where they are. Our engineers don’t create products in a vacuum, sitting behind a desk. Instead, we trust our connection with our customers and create products that answer a customer’s specific needs. This blog explains how Cross Wrap’s products are created with an innovative mindset.

Innovation happens when discussing with customers

Ideas for new solutions surface in direct contact with our existing or potential customers. A need can be identified in various stages of discussions with the customer. Everyone representing Cross Wrap has a duty to bring forward new information and emerging challenges or trends in the recycling field.

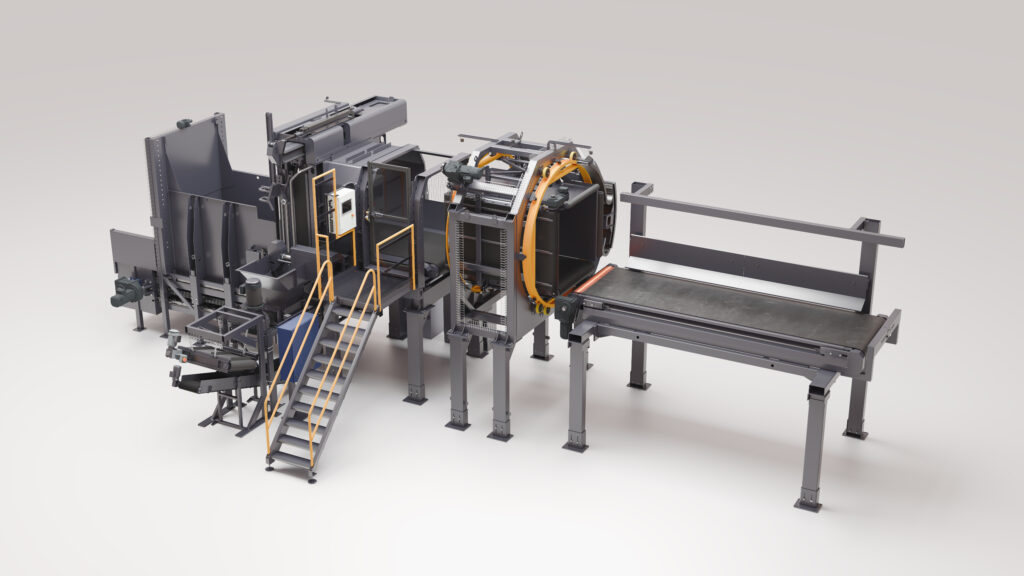

Firstly, as our personnel travel around the world, they form a picture of the possible obstacles that facilities may have to overcome to keep their recycling business profitable. A good example of answering those needs is the Cross-dewiring machine, or more accurately, the Cross Dewiring Unit. In the field, it was evident that the recycling facilities didn’t have a solution for opening cross-wired bales, even though they’re widely used. This idea of an attachment to an already existing machine took its time to develop, going through various meetings with the product development, sales and executive teams.

However, product development at Cross Wrap doesn’t always take that long. The second stage, and a way to listen to our customers before producing something new, is to spot a need a specific customer has during a sales process. During those discussions we make an assessment if other customers have similar needs. If the answer is yes, then our engineers work on a solution for the specific problem. The customer is happy, and we have a new solution to offer to other customers. For example, the Bale stacking device has started its journey like this.

“A good example of to customer and industry needs is the Cross-dewiring machine, or more accurately, the Cross Dewiring Unit. This idea took its time to develop, going through various meetings with the product development, sales and executive teams.”

The development of the Cross Dewiring unit is a great example of our innovation process.

The third chance for us to innovate is the installation stage. When a customer has bought a product from us, we always pay a visit and install the new machine or at least make adjustments. We always train the personnel to use the new equipment. As every facility is different and may just be starting its operations, at this stage the need for some improvements might be spotted. For example, our client realised that it’s difficult for forklift drivers to move the bales around. From that discovery, the Bale flipping table was created.

In the case of machine attachments, like the Bale stacking device and the Bale flipping table, the developing process takes a few months. Our advantage is an agile and efficient way of working without unnecessary bureaucracy. The process includes a business analysis, mechanical and automation design and testing the machine internally. After that the prototype is ready for the customer to test.

The true functionality of new solutions is seen on site

The true functionality of a new solution is measured in the customer’s facility, with real material flows and operations through the operation line.

We test our new products and machine attachments at our facility in Finland. However, the true functionality of a new solution is measured in the customer’s facility, with real material flows and operations through the operation line. That’s why we make sure that the customer is never left alone when it comes to developing new products for them.

Every pilot project has a named project manager who stays in close contact with the customer through the testing process. If something doesn’t work smoothly at the facility, we send an expert to investigate. The challenges might be caused by the new machine itself, the process surrounding it, the way the machine is being used, or some or all of those. It’s important to take time with the fixing, so that we can target the right corrections to the right place.

Collaboration with a customer is a win-win-situation for both parties. In Sweden, a new product was developed with close contact with a client. Check out our reference and learn how we developed the Coil shredder with Svensk Plaståtervinning.

We are problem solvers

“Collaboration with a customer is a win-win-situation for both parties.”

Innovating doesn’t only cover the machines and technical solutions, but also services and collaboration. Our Life cycle service has a good reception. We continue to be flexible and listen to our customers and develop our services as well as our product portfolio.

We are always eager to deepen our knowledge of operations in plastics, paper and waste to energy sectors. We focus deeply on the fields and operations we know best. We aim for modularity so that there are many possible layouts of our machinery at each facility. Customers as well as potential customers are integral part of our innovation process and their challenges drive us forward. We are here to help, so let’s tackle those challenges together.

Mirja Yli-Erkkilä

Chief Commercial Officer

Cross Wrap Oy