NEWS

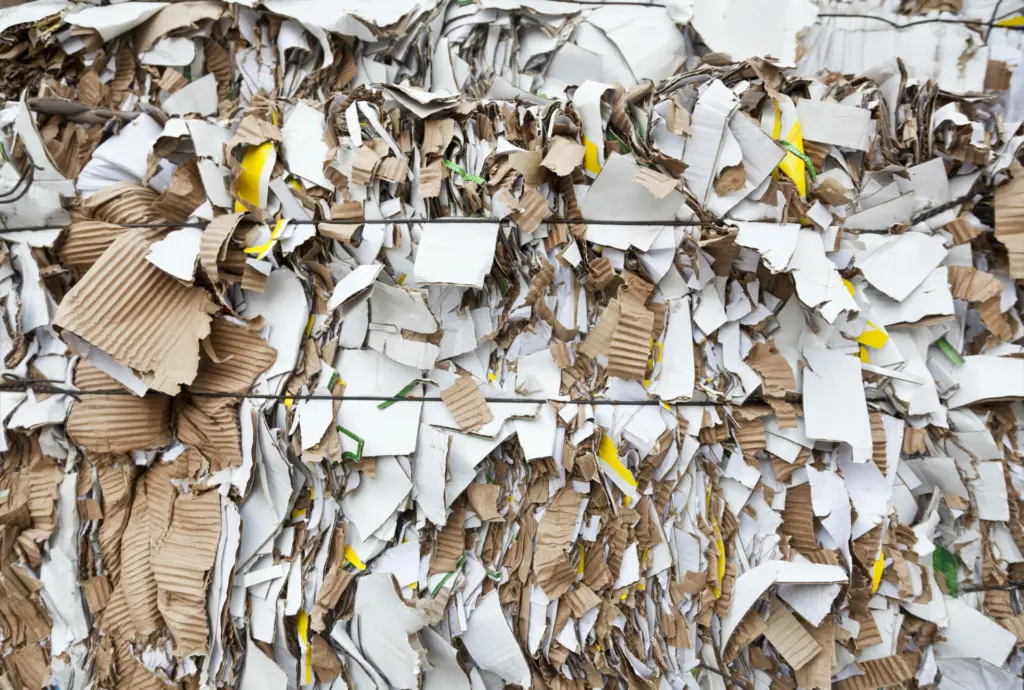

Stock preparation in paper making and recycling: How to boost performance with the help of automation

How to maintain high-performing stock preparation when inflation is pushing the prices up in labor costs and there is a growing need for energy savings?

An effective stock preparation process is the base for a competitive paper-making and recycling process. Today it is more and more important to reduce energy consumption while keeping the process running efficiently.

Automation and smart material handling practices offer solutions that help to keep the process competitive, whether your plant is operating with recycled fibers or virgin pulp.

Read ahead and learn how automated bale dewiring and handling can improve stock preparation and material feeding in the paper industry.

The material price fluctuation creates a more unpredictable market

The paper industry market has recently seen turbulent times and situations that could not be predicted. The industry has been recovering from the Covid-19 era, for example, globally affected logistics and production chains.

When the market started to open slowly after restrictions, the paper industry was hit with unexpected price settings. The price of the recycled paper has been dropping, which means more unpredictable times for recyclers.

On the other hand, the lower price makes the recycled material more attractive for paper mills. Now that it is cheaper to use recycled paper, many will take advantage of the situation whilst also considering sustainability.

One thing is for sure. When the market is unpredictable, it is increasingly important to focus on the daily work that keeps the process high-performing. And this is when automation takes hold of stock preparation.

The benefits of automated material feeding

Automation is not the one magic solution for everyone, but when you automate your process from the right place, you can boost many of the upcoming stages also.

The Dewiring Machine offers a more effective workflow for the feeding and stock preparation process. The machine automatically cuts and removes bale wires from different sizes of bales and coils the wires into neat bundles.

Are you processing both horizontally wired and cross-wired paper bales? Open both bales automatically and efficiently with our Dewiring unit!

This not only removes the need for manual work but also makes your process faster, safer and more reliable with increased capacity. The machine opens the bales on the conveyor to be ready for the pulper.

During operation, the machine only needs minimal supervision and can be remotely operated easily by the person loading the bales with the forklift. The bales are loaded into the feeding conveyor, and the smart sensors detect the bale sizes and even weights. Then the machine cuts and removes the wires without any manual work needed.

Whilst running, when the machine is waiting for the new bale, it can automatically turn its hydraulics off, which saves energy. When there is a new bale fed to the conveyer, the machine starts automatically. The machine also waits for the feeding information coming from the rest of the stock preparation line and can thus wait for permission when to feed material into the process.

Automation can also help improve the material’s quality, especially regarding the recycled paper. When the wires are removed, they do not end up in the pulper and where they form a non-recyclable reject mass.

The benefits of automated wire removal are multiplied later in the process. The wires do not wear out other equipment, reduce the quality of the material, or cause surprising repair costs because they are removed from the process early.

Scale up without additional costs

One of the biggest benefits of automatic bale dewiring is that you can easily respond to changes in demand. If, in the past, material has been fed manually, increasing the capacity has required human labor in the same proportion.

Increasing the capacity easily is an advantage, especially now that the material is cheaper. You can utilize ever larger amounts of material without making other changes to the process.

The capacity of the dewiring machine can be up to 60 bales per hour or 80 tons per hour with Cross Wrap solutions. This requires proper quality bales with big enough weight. Usually, the restricting factor is never the Cross Wrap machines capacity but the capacity of the rest of the line.

And when it comes to the pulper reject material, the cross wrapping also offers many benefits to work smarter and cut costs. You can handle, transport, and store the materials with automated and smart solutions that don’t require additional shifts to the process.

Cross Wrap solutions for stock preparation

Dewiring Machine

- Automatic dewiring machine, which removes the steel wires from recycled and virgin paper bales.

- Coils the wires into clean bundles, which makes them easier to recycle.

- Easy to place: It can also be placed outdoors under the roofing.

- Very energy efficient compared to other machines: use 25 kW/h on average whilst running.

Read more: Dewiring Machine

The Cross Wrap benefits for your stock preparation

- Wires don’t end up in the pulper, as they are removed beforehand.

- The need for maintenance is predictable, as there are no excess wires in the pulper. This also improves the quality of the pulp.

- The waste generated during the processing of the material is easier to handle.

- Scale capacity without rising costs, as the feeding is automatic and smart.

- Capacity changes are easy, as the feeding is automatic and wires are removed.

- The working safety and ergonomics of the facility are improved, as you can remove repetitive manual tasks.

Success story: Less work needed in stock preparation

Papierfabriek Doetinchem bv produces over 70 000 metric tonnes of 100% lightweight (MG) papers yearly from recycled materials. The mill has created its recipe for pulping, as the feedstock consists of various-sized paper and cardboard bales.

The Dewiring Machine has improved the stock preparation and the whole process’s efficiency and safety. As the feed of the material is automatic and wires are automatically removed, there has been a significant improvement in the whole process.

“We saw the improvements in our process straight away when we started to use the Dewiring. Now there is less work needed in stock preparation and the removed bale wires are much easier to store and handle after they are nicely coiled by the Dewiring machine,” Ruud Rijks, the production coordinator for Papierfabriek.

Ask for solutions to boost stock preparation in paper-making and recycling

Do you think you could boost your material flow in the stock preparation process?

With our solution, you can deliver a more cost-efficient, top-quality end product. We have a long history of partnering with global market leaders in paper recycling and processing.

When you want to improve your stock preparation process in the paper industry, contact us sales@crosswrap.com

More news

Inspired by this case? Want to solve your own crosswrap challenge?

Leave us a message, and our expert will get in touch to discuss your case.

"*" indicates required fields